Personnel on the field were given Android phones for recording results of quality inspections.

Personnel on the field were given Android phones for recording results of quality inspections.

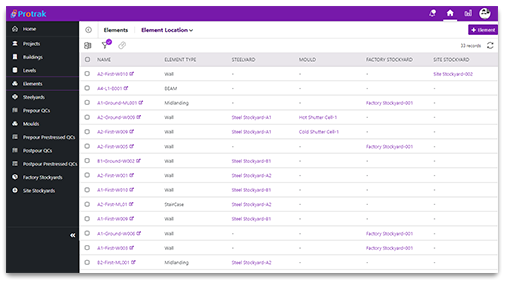

Provided ability to identify each element by QR Code to track/ update it’s status using mobile device.

White-boarding on mobile to precisely document the problems while reporting quality issues.

Geolocation for elements in transport and locating elements in stockyards.

In areas of no network connectivity, the app could be used to record actions offline and sync with the server when connectivity is available.

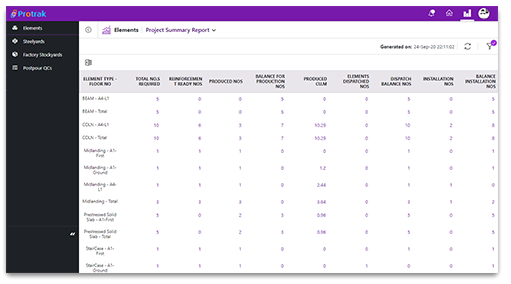

Developed customizations based on operational data collected to produce custom reports and analytics.

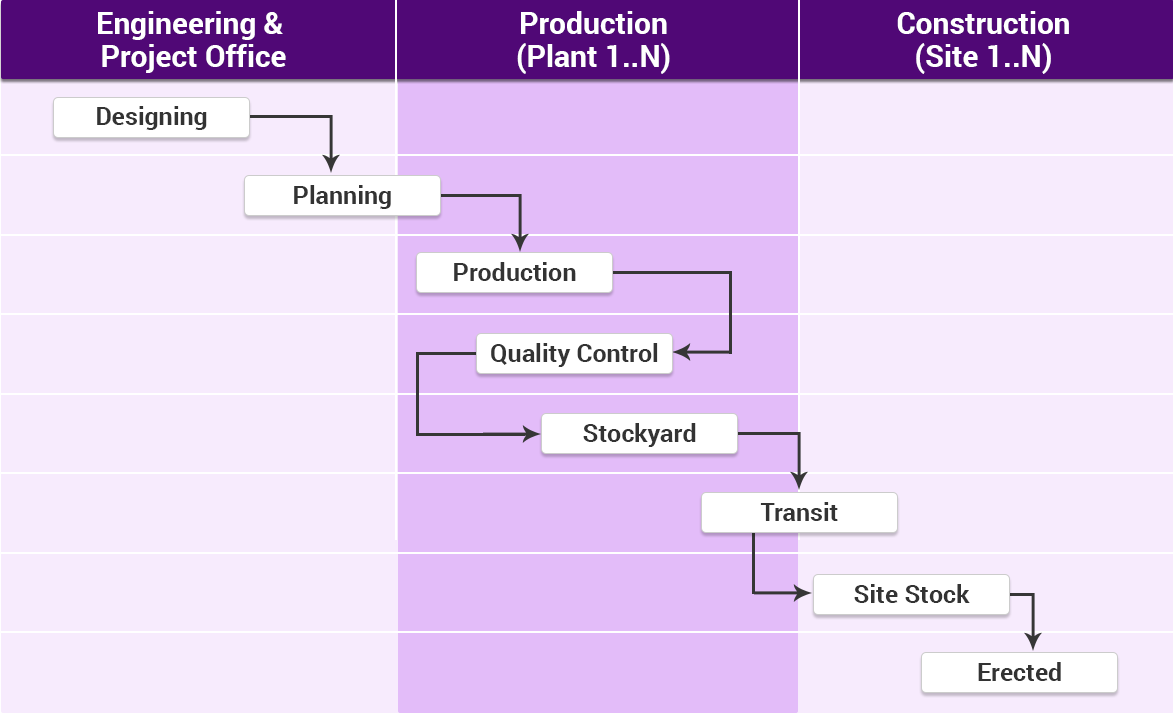

Real-time visibility of project status has helped to have better tracking and control on the project.

Improved productivity by clear identification of actionable items of users, easy and quick location of elements in stockyard.

Targeted messages between users have improved communication and collaboration between planners and personnel on the production floor and construction site.

Wealth of data generated by activity list / history tracking of each component has helped in process improvement and faster audits.

Improved security and accuracy of project specific data due to strong user and role based access control.

Since the implementation, the usage of Protrak platform has been extended to leave management, fixed asset tracking and QA/QC process management.